By Category

By Type

By Author

-

How immense is farming’s problem with plastic?

-

Giving food a bad wrap: Why we need to stop relying on plastic

-

Preserving the practices of traditional foods

-

How our paranoia about contamination is threatening local food

-

The Puglia paradox: Why pest invasions and historically high prices could actually be good for olive oil

-

Roots to regeneration: Growing regenerative leadership in food and farming

-

Reviews: Food and farming in film 2024

-

Understanding the farmer protests

-

What is ‘local’ food and why does it matter?

-

For the love of Cawl

-

For the love of home-cooked food

-

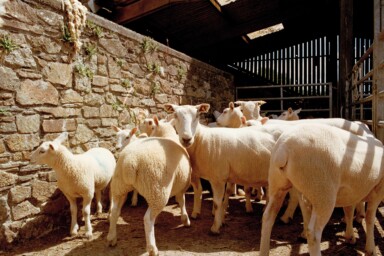

More than a by-product: Resetting the way we think about wool

-

Beans are good for people and the planet, so why aren’t we eating more of them?

-

Progress for local abattoirs at ORFC

-

Views from ORFC: Inspiration for food and farming in 2024

-

ORFC 2024: Highlights from this year's conference